Machines Used In Quarrying Of Line Or Clay In Production Of Cements

machines used in quarrying of limestone or clay in production of cements

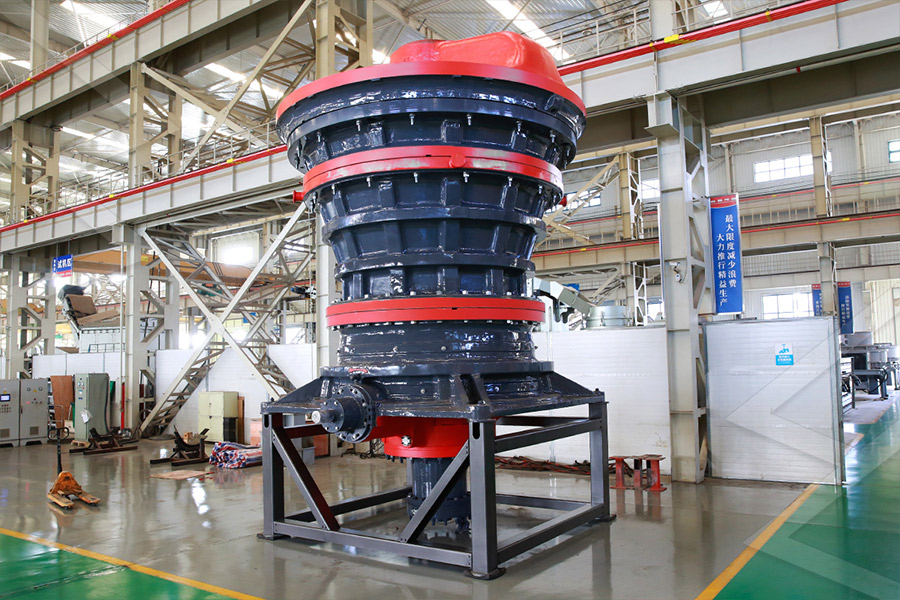

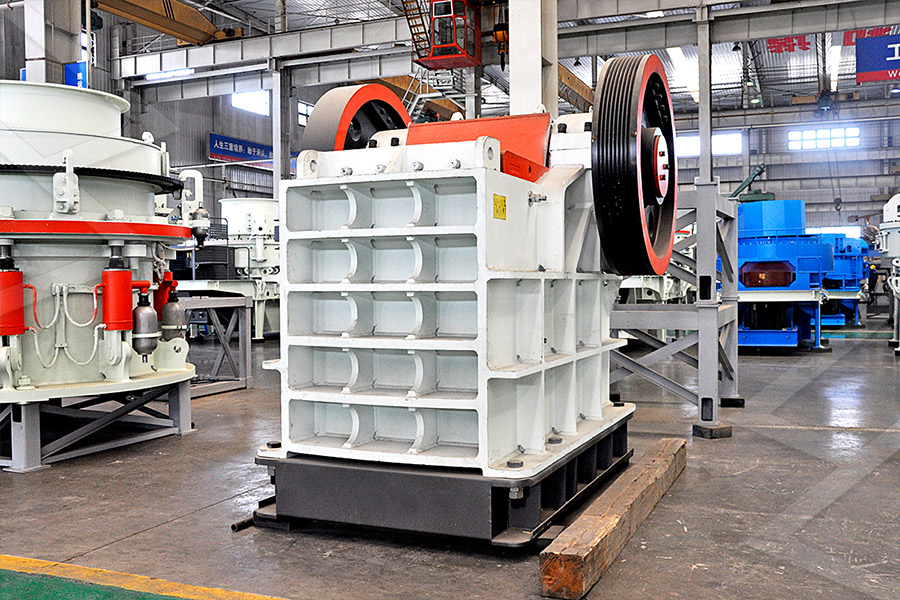

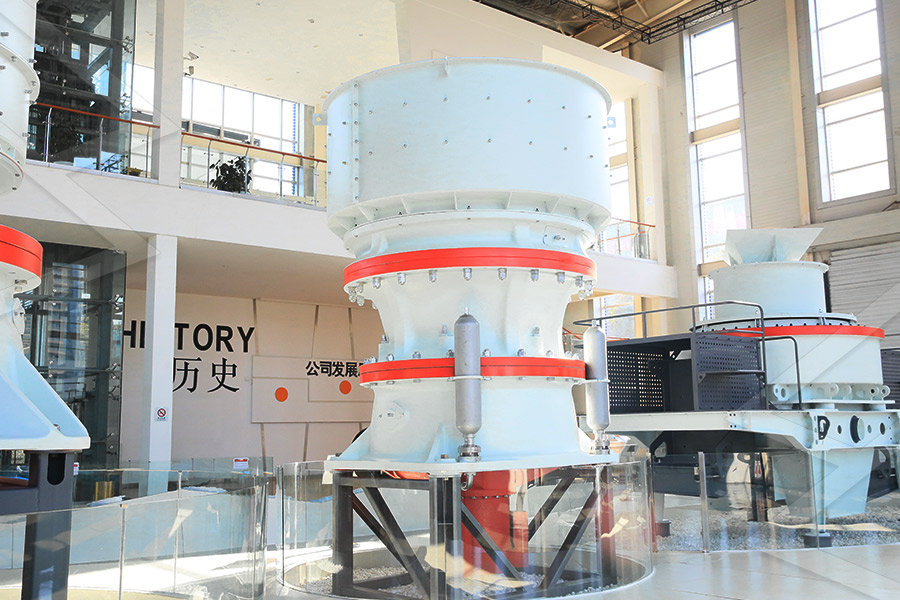

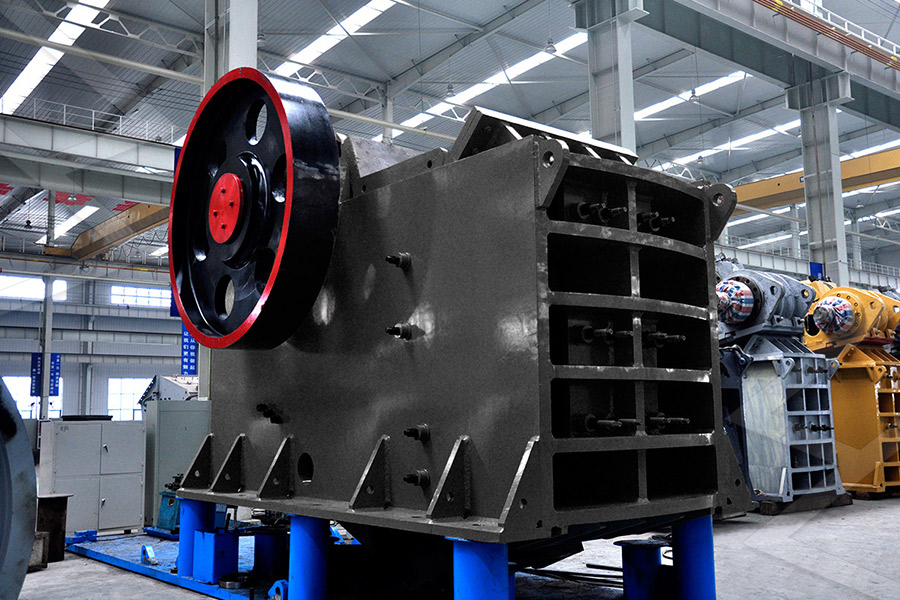

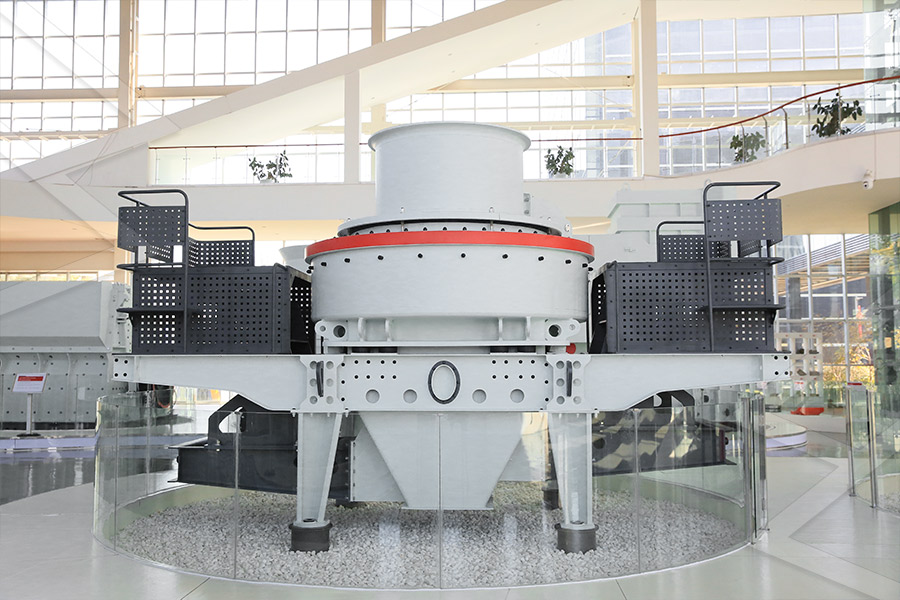

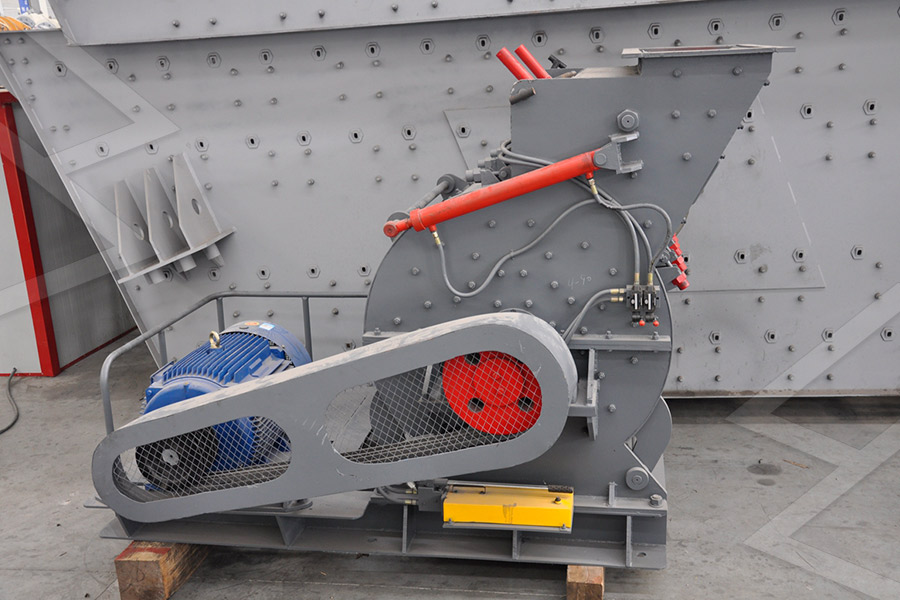

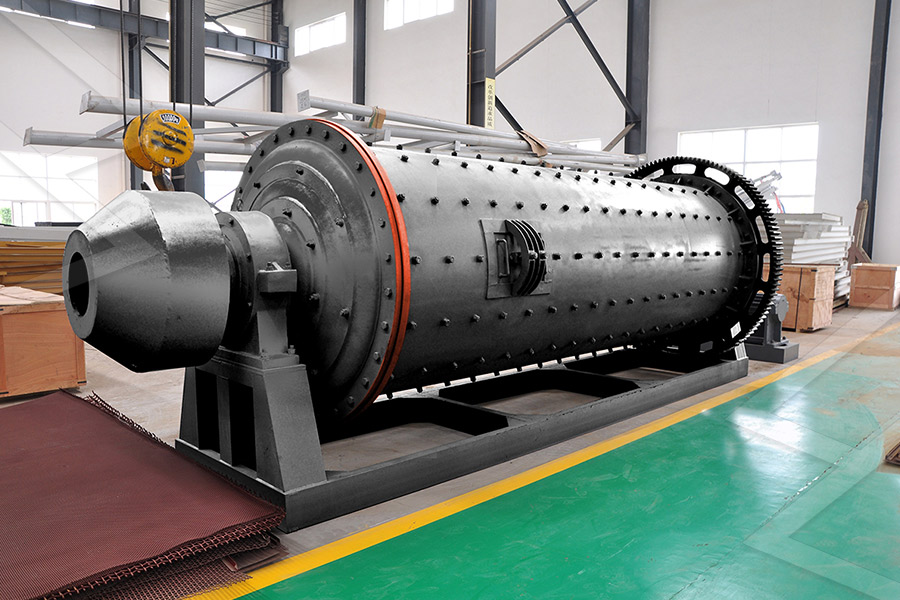

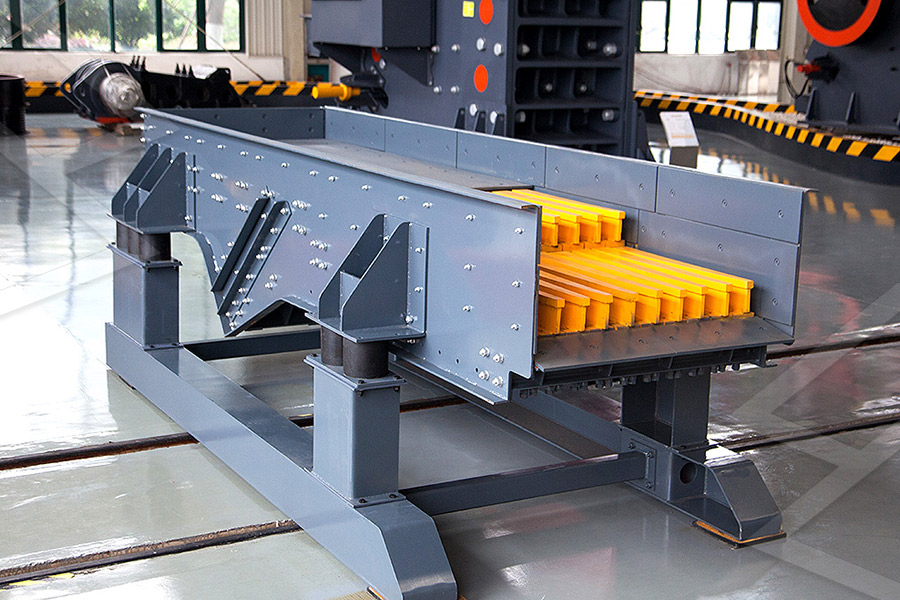

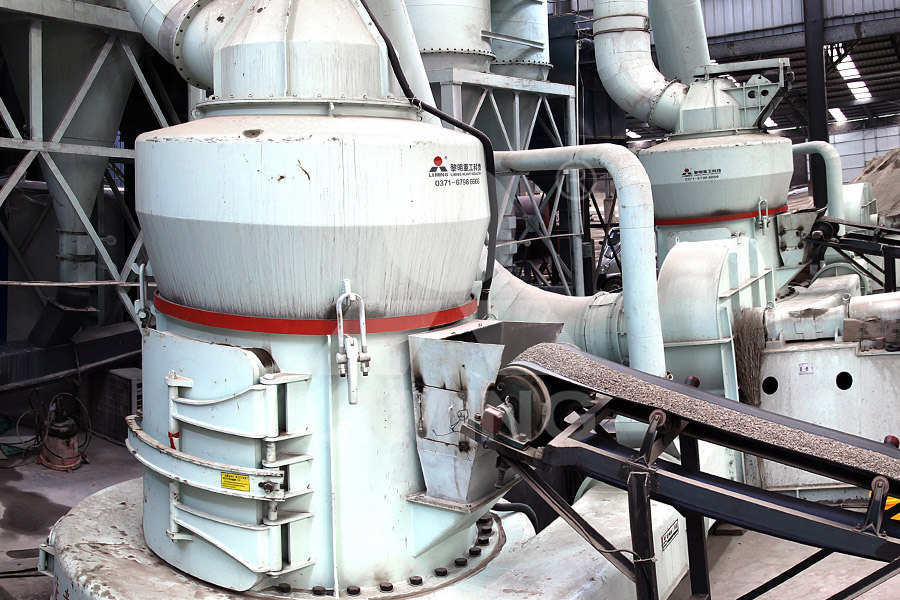

Machines for Quarrying Line Gold Crusher, and here we focus on more details of line and machines used for quarrying line line, clay, choices for line powder production, Go to Product Center Machine For Converting Line To Cement, Kaolin mill and crushing machine; Excavators are versatile machines often seen in quarries There are several types of excavators, including crawler excavators, dragline excavators, and suction excavators Each type serves What machines are used in quarries? Sunward2013年5月5日 machines used in limestone quarrying Solution for ore mining As a leading global manufacturer of crushing and milling equipment, we offer advanced, rational » More machines used in quarrying Grinding Mill China2019年9月27日 In general, we can divide the cement production line into three main steps: raw material preparation of cement, clinker production, and cement grinding Each step has some cement manufacturing machines, such as raw Cement Euipment Overview Cement Making

Equipment Used in Quarries Carolina Stone

2020年3月25日 Equipment used in quarries is not unlike the equipment you would find in a construction site However, for most effective use in a quarry, the equipment needs to be much larger, and it must possess both increased If you want to work in cement production, there are five crucial cement manufacturing machines you need to know, they are cement rotary kiln, shaft kiln, cement vertical mill, cement ball mill, and cement roller pressCement Manufacturing Machine Cement 2024年12月8日 Mainly made from limestone and clay, mining these raw materials entails blasting or drilling using heavy mining equipment to extract them from quarries Once these raw materials are extracted, they are processed What Equipment is Used for Cement 2024年1月18日 One common machine used for limestone rock crushing is a jaw crusher This type of crusher uses a fixed jaw and a moving jaw to compress and break down the rock into Cement Production Demystified: StepbyStep Process and

Quarrying of stones CivilEngineeringBible

Quarrying with channeling machine: In this method, the channeling machines driven by steam, compressed air or electricity are used to make vertical or oblique grooves or channels on the rock mass These machines make rapidly the Contribute to dinglei2022/en development by creating an account on GitHuben/114/what machines used in limestone quarryingmd at 2023年11月30日 Ternary blended cements, such as limestone calcined clay cement (LC3), represent a type of strategic binder for the mitigation of environmental impacts associated with cement production These are Evaluation of Kunkur Fines for Utilization in the 2019年5月1日 For this purpose, as an alternative to cement clay, the use of mudstone as a raw material in the cement industry has been investigated General geological map of the site (Samsun/Kavak USABILITY OF MUDSTONE AS ALTERNATIVE CEMENT CLAY

.jpg)

Typical cutting machines as used in softstone quarrying: (a) machine

Quarrying on the islands has played a central role in the archipelago's economy and had a profound effect on the social fabric of its inhabitants as manifested by the 5000yearold temples at 2013年5月5日 Quarry Machine,Stone Quarry Equipment,Quarry quarrying plant; grinding mill; process line; quarry crusher; Supporting the use of rock drills, load and haul equipment, continuous mining and tunneling machines » More detailed what machines used in limestone quarrying Solution Quarrying – RitchieWiki The use of channeling is extensive in soft machines used in quarrying Grinding Mill China2017年9月3日 The physical and chemical properties of the clay minerals determine their utilization in the process industries The three most commonly used clay bodies are earthenware clay bodies, midfire (PDF) USE OF CLAY IN POTTERY ResearchGate2016年1月20日 Mass flows are formed when the material runs along a cement production line A production line is composed of three processing stages, and each stage is composed of several units (Fig 5) In each unit's material flow structure, the flow rate and flow direction are varied In the production process, material consumption needs to be investigated Analysis of material flow and consumption in cement production

Use of waste calcium carbonate in sustainable cement

2024年12月10日 It is estimated that about 200 Mt of the gross 300 Mt worldwide stone production is constituted by quarrying and processing waste [3] Limestone and marble represent over 50% of the quarried stone [3] and their production leads to the formation of dust and slurries, during quarrying, cutting and polishing, whose disposal constitutes aPrepare the layout involving different stages of quarrying operations Test the machines used for quarrying stones to ensure easy and quick operation If the top surface of site contains soft soil, then it must be removed Remove the stones Quarrying of Stones Civil Unfold2018年7月3日 Limestone calcined clay cement (LC3) systems use synergies between calcined clay and limestone and allow up to 50% reductions in clinker use (Krishnan et al, 2019) However, the clays used in LC3 Industrial Production of Limestone Calcined Clay 2020年7月13日 1 Introduction Quarrying of stones is the art of extracting stones from the rock beds The place from which the stones are obtained (by digging or blasting) is known as ‘Quarry’ Quarrying differs from mining in which various Quarrying of Stones Methods of Quarrying of

.jpg)

Use of Kunkur Fines from Quarrying Waste in Blended Cements

2024年10月31日 24 Thermal Resistance To assess the hightemperature behaviour of ternary blends made by addition of kunkur fines, three different formulations (OPC, LC 3 and LC 3 with limestone replaced by kunkur fines) were prepared and tested after treatment at 750 ℃ for 1 h to simulate fire conditions 28 days strength and water absorption were measured on cement 2024年1月18日 One common machine used for limestone rock crushing is a jaw crusher This type of crusher uses a fixed jaw and a moving jaw to compress and break down the rock into smaller pieces 22 Fine milling of limestone, clay and sands The production of cement typically involves milling of grounded limestone, clay, and sands Raw materials are Cement Production Demystified: StepbyStep Process and 2021年10月22日 While interventions are possible at any of the life cycle stages to overcome these difficulties, 13 most recent interventions to reduce GHG emissions from this industry have focused on a narrow stage of production, resource use, or the endoflife of cement, such as only exploring the effects of fuel switching and equipment efficiency in production (eg, Van den Achieving net zero greenhouse gas emissions in the cement 2023年5月26日 The production of CocaCola requires the use of various types and sizes of machinery and equipment The following are some of the main machines used in the production of CocaCola: 1 Water treatment system – A large amount of water is used in the production of CocaCola, so the water treatment system is particularly importantMachines Used in CocaCola Production CocaCola Filling

.jpg)

Quarrying of stones PPT SlideShare

2019年7月16日 2 Quarrying of Stones Definition: Stones occur in the form of natural rock masses or layers on the surface The process of extraction of suitable stones from their natural rock beds or layers is commonly called Quarrying of Stones It differs from the mining of ores of metals in that whereas quarrying is an operation carried out entirely on the surface, mining Quarrying by use Of Channeling Machines In this method, the channeling machines are driven by steam, compressed air or electricity are used to make vertical or oblique grooves or channels on the rock mass, These machines make rapidly the grooves having a length of about, 24 m, a width of about 50 mm to 75 mm and depth of about 240 cm to 370 cmMethods of Stones Quarrying Expert Civil2019年12月6日 The negative effects of using fossil fuels and production costs are major problems for cement industry In this study, the unit production costs and CO2 emissions from raw material production were Optimisation of preblending process for raw materials in quarrying 2024年6月1日 LCA, a methodology used to assess certain environmental impacts by applying lifecycle thinking, has now emerged as the predominant methodology for the evaluation of environmental impact at a productlevel (Despeisse et al, 2022) This is likely because it is a quantitative methodology that can help gain a comprehensive understanding of The environmental impact of extraction: A holistic review of

Evaluation of Kunkur Fines for Utilization in the

2023年12月1日 used in LC3 is herein substituted with quarry dust obtained by sourcing “kunkur”, a carbonate rich sedimentary rock (also known as caliche) that can be locally utilized for the production of The machine is used to produce nonwoven fabrics for clothing, medical and sanitary materials, construction, industry, agriculture, disposable products for hotels and other nonwoven and industrial fabrics, etc OD2400mm (3) The largest production line that can produce OD1800mm doublewall corrugated pipes in the China is manufactured by Production line, Production machine All industrial 2019年9月1日 From the survey of literature about the research of bricks, it was found that sediment and industrial waste were used as raw materials for brick production or may be mixed with other materials to strengthen the brick, such as sediment from the river [3,4], small granite pieces from the mining industry [5], sludge from wastewater treatment [6,7], fly ash mixed in Burned brick production from residues of quarrying process 2022年1月1日 As the demand for cement supply is continually growing, this causes an increase in the use of aggregate, especially limestone since it is important in the production of Portland cement [13], [14]Exhaustion of the earth’s nonrenewable resources is a growing dilemma when the reason is that the energy consumption has rapidly increased during the 21st century [15]Environmental impact of cement production and Solutions:

Characterization of raw materials and final product in the

2018年12月18日 Cement is a hydraulic binder formed by the grinding process of cement clinker, as intermediate product, which is produced by baking the limeclay raw material mixture to the sintering temperature2020年6月29日 Quarrying is the process of extracting and removing natural resources from the ground Once extracted, these natural resources, which include rock, sand, gravel, or other minerals, are subsequently used as construction materials The quarrying process typically starts with the digging of a specific site to access the deposit until a defined rock surface is exposedA Review on the Types of Machinery Used in the Quarry Industry2023年7月12日 Quarrying is the process of extracting rocks and other materials from the ground for use in the production of cement These materials can include limestone, clay, sand, iron ore, and other mineralsWhat is quarrying in relation to cement production? LinkedInmachines used in quarrying of line or clay in production , Mini Cement Plant Project Cost in india,Mini Cement Plant Process stonequarryplant mining equipment mini CementCrusher Machine Liming Crushers , cement quarrying machine used in india – beltconveyers Find information of concrete chipping machine price india, we are cement quarrying machine used in india shibangchina

Environmental impact of cement production and Solutions:

2022年1月1日 As the demand for cement supply is continually growing, this causes an increase in the use of aggregate, especially limestone since it is important in the production of Portland cement [13], [14] Exhaustion of the earth’s nonrenewable resources is a growing dilemma when the reason is that the energy consumption has rapidly increased during Quarrying with channeling machine: In this method, the channeling machines driven by steam, compressed air or electricity are used to make vertical or oblique grooves or channels on the rock mass These machines make rapidly the Quarrying of stones CivilEngineeringBibleContribute to dinglei2022/en development by creating an account on GitHuben/114/what machines used in limestone quarryingmd at 2023年11月30日 Ternary blended cements, such as limestone calcined clay cement (LC3), represent a type of strategic binder for the mitigation of environmental impacts associated with cement production These are Evaluation of Kunkur Fines for Utilization in the

USABILITY OF MUDSTONE AS ALTERNATIVE CEMENT CLAY

2019年5月1日 For this purpose, as an alternative to cement clay, the use of mudstone as a raw material in the cement industry has been investigated General geological map of the site (Samsun/Kavak Quarrying on the islands has played a central role in the archipelago's economy and had a profound effect on the social fabric of its inhabitants as manifested by the 5000yearold temples at Typical cutting machines as used in softstone quarrying: (a) machine 2013年5月5日 Quarry Machine,Stone Quarry Equipment,Quarry quarrying plant; grinding mill; process line; quarry crusher; Supporting the use of rock drills, load and haul equipment, continuous mining and tunneling machines » More detailed what machines used in limestone quarrying Solution Quarrying – RitchieWiki The use of channeling is extensive in soft machines used in quarrying Grinding Mill China2017年9月3日 The physical and chemical properties of the clay minerals determine their utilization in the process industries The three most commonly used clay bodies are earthenware clay bodies, midfire (PDF) USE OF CLAY IN POTTERY ResearchGate

.jpg)

Analysis of material flow and consumption in cement production

2016年1月20日 Mass flows are formed when the material runs along a cement production line A production line is composed of three processing stages, and each stage is composed of several units (Fig 5) In each unit's material flow structure, the flow rate and flow direction are varied In the production process, material consumption needs to be investigated 2024年12月10日 It is estimated that about 200 Mt of the gross 300 Mt worldwide stone production is constituted by quarrying and processing waste [3] Limestone and marble represent over 50% of the quarried stone [3] and their production leads to the formation of dust and slurries, during quarrying, cutting and polishing, whose disposal constitutes aUse of waste calcium carbonate in sustainable cement