Continuous Grinding Ball Mills

.jpg)

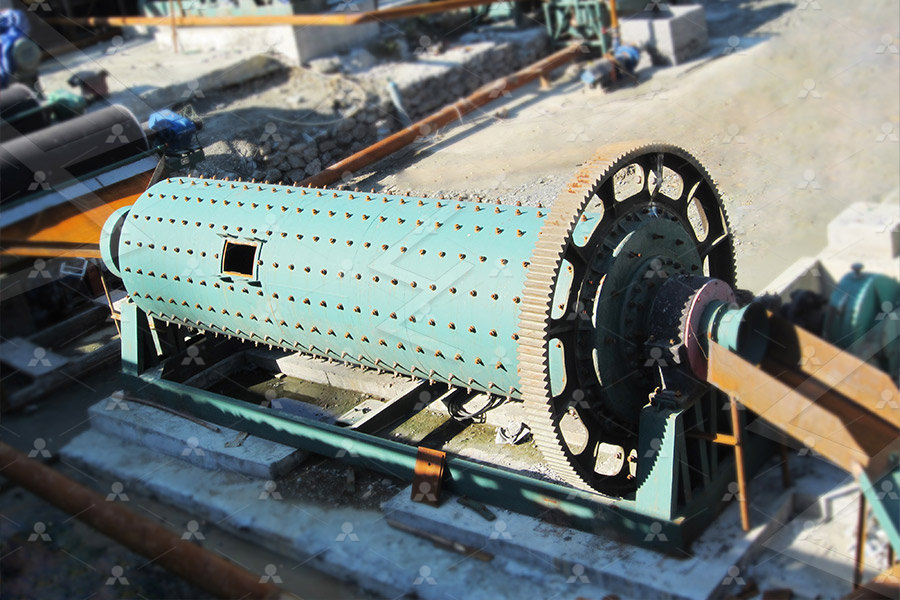

CONTINUOUS BALL MILL

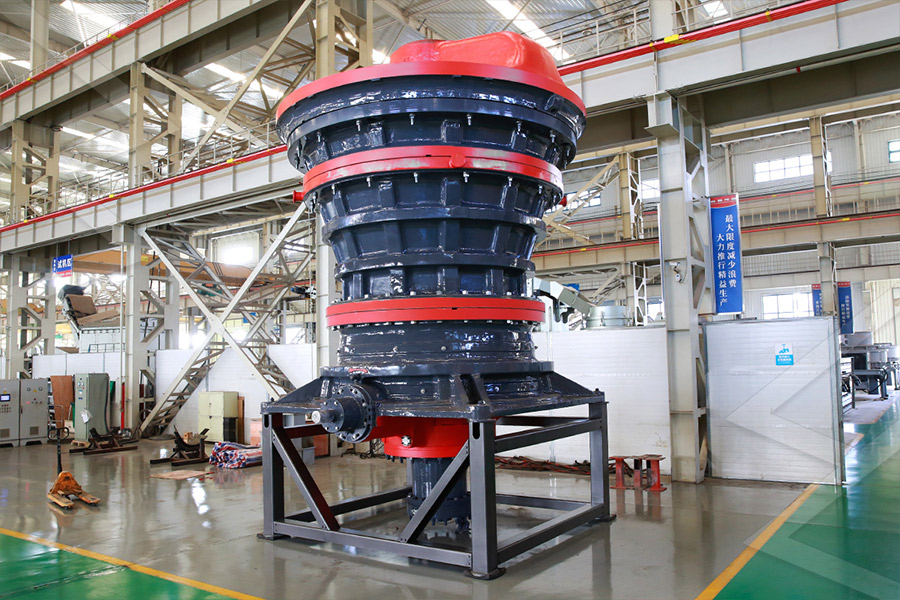

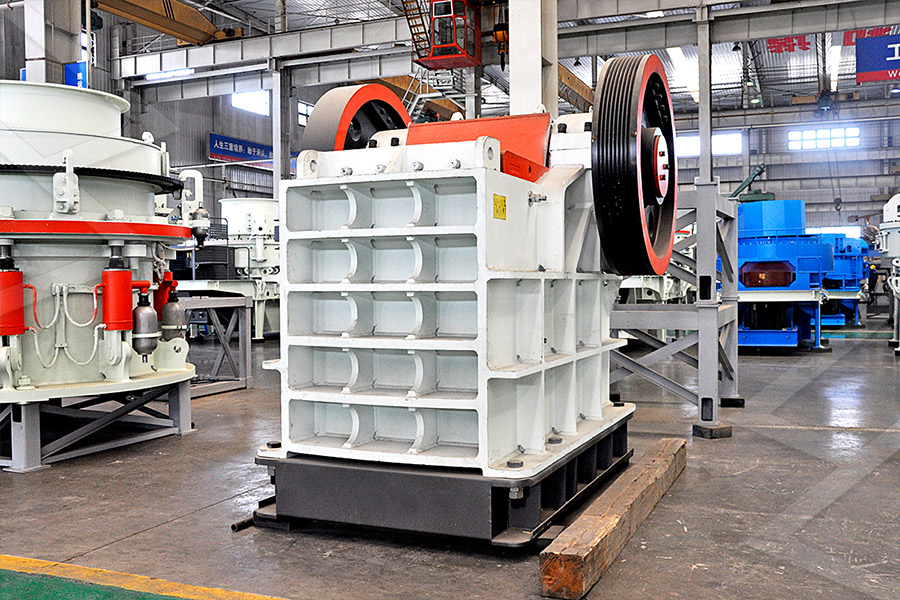

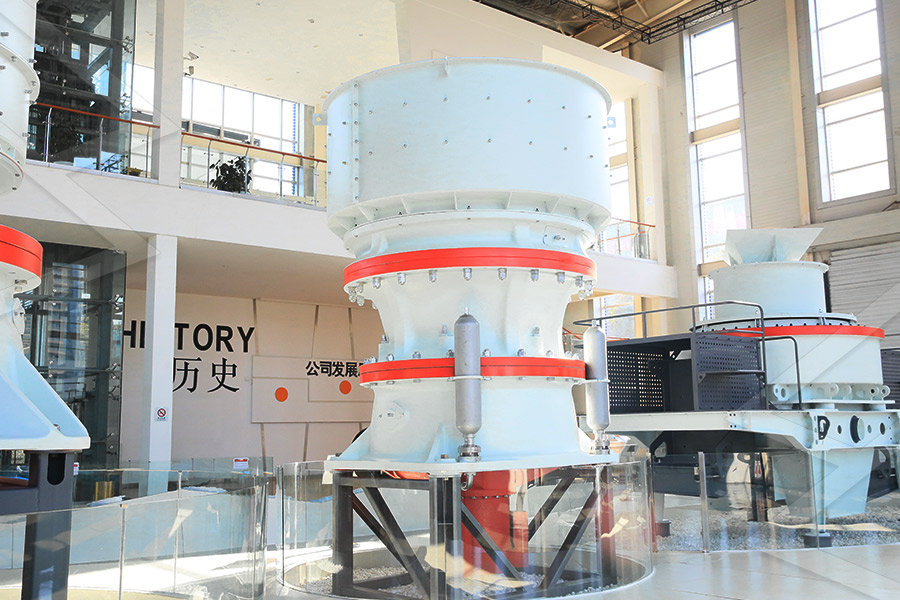

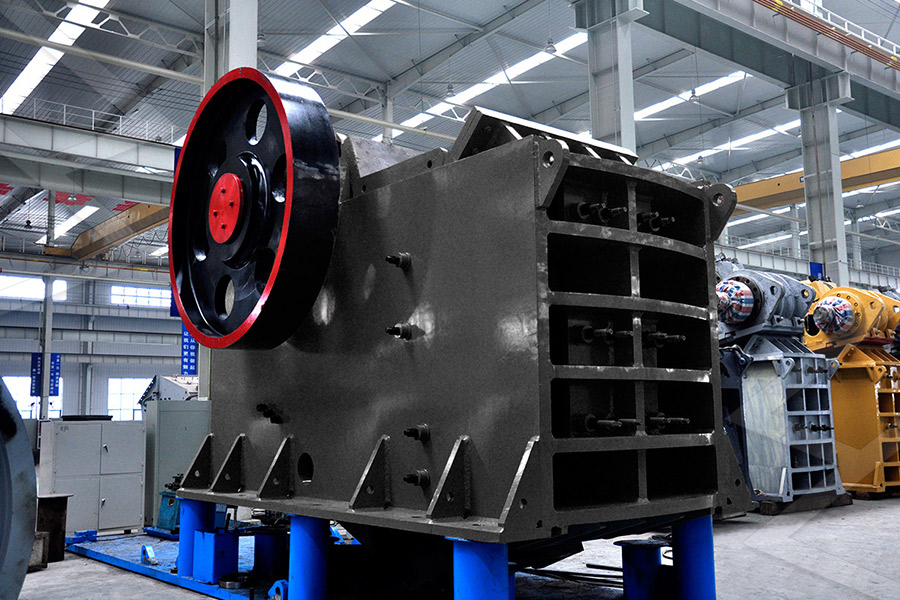

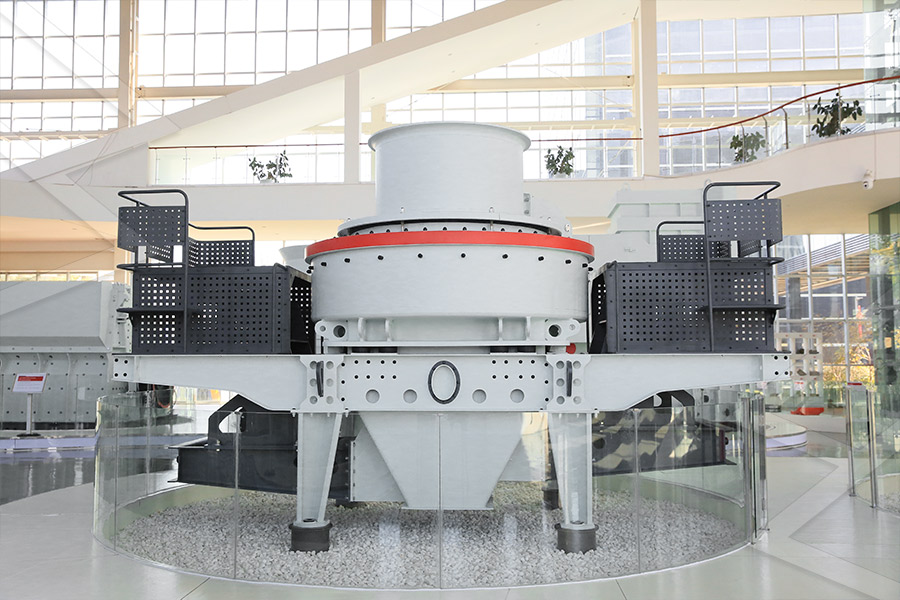

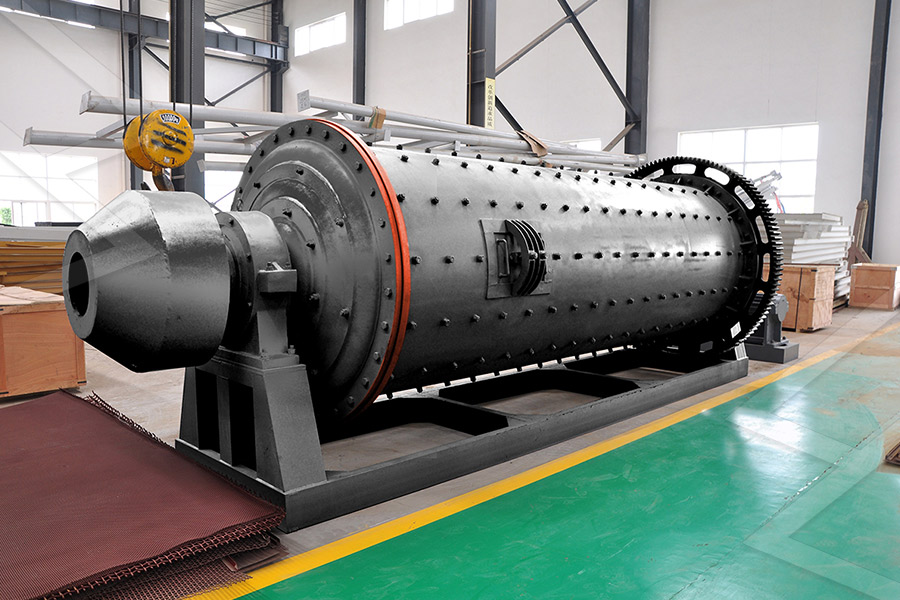

The continuous ball mill is a ball grinding mill that can realize both wet grinding and dry grinding for 24 hours without any downtime AGICO, as a continuous ball mill manufacturer, offers highefficiency ball mill grinders for customersIn the process of material grinding, the continuous ball mill adopts a continuous and uninterrupted form for feeding, grinding, and discharging According to different operation process, ball grinding mill can be divided into continuous Continuous Type Ball Mill for Industrial Use ball Conical Ball Mills: Also known as tapered mills, these mills have conicalshaped liners and grinding media, which increase the efficiency of grinding Conical ball mills are suitable for both coarse and fine grindingBall Mill Grinding Machines: Working Principle, Continuous ball mills provide a seamless and uninterrupted process for feeding, grinding, and discharging materials, offering versatility in both dry and wet grinding operationsContinuous Ball Mill Continuous Ball Mill Manufacturer

Continuous Ball Mill Project Laarmann Group BV

Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls An internal cascading 2023年5月24日 The main differences between batch ball mills and continuous ball mills are as follows: 1 Grinding capacity: Batch ball mills have a smaller grinding capacity than continuous Comparison between batch ball mill and continuous ball mill Fine milling of Minerals, metal products, chemical powders, agrofood pharmaceutical (organic inorganic) powders Batch process or continuous process For wet or dry products Various sizes for different grinding Ball Mill Continuous process Lessine2021年3月4日 PATTERSON Continuous Ball, Tube and Rod Mills are designed for open or closed circuit grinding under the most severe and exacting applications By proper selection of Patterson Industries ContinuousType Ball Pebble Mills

.jpg)

Continuous Mills SolidsWiki

2022年7月7日 The Continuous Mill is a horizontal rotating device transmitted by the outer gear The materials are transferred to the grinding chamber through the quill shaft uniformly There are ladder liner and ripple liner and different 2024年4月16日 XMQL φ 420×450 (900) grate continuous ball mill classifier is φ 150×1200 (1600) double screw conveyor, in order to match with φ 420×450 (900) specification cylinder XMQL Φ420×900 ZJH minerals2022年11月1日 In this context, modeling of fullscale continuous ball mills could provide significant insights and help process design (King, 2001) Ball milling, where balls hit and grind particles in a rotating horizontal tube, is reported to be an inefficient unit operation (von Seebach et al, 1996, Fuerstenau and Abouzeid, 2002)Impact of ball size distribution, compartment configuration, 2012年6月1日 continuous steady state mills, the size reduction is treated as a continuous process Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate (PDF) Grinding in Ball Mills: Modeling and Process Control

.jpg)

Experimental characterization of chalcopyrite ball mill grinding

2021年11月1日 The energy consumptionbased characterization of different chalcopyrite grinding processes, performed in ball mills using both batch and continuous flow processing modes, is discussed in this section 41 Materials and 1973年6月1日 REFERENCES 1 D F Kelsall and K J Reid, The derivation of a mathematical model for brealage to a small continuous open circuit wet ball mill, Proc A 1 Ch E II Chem E Joint Meeting, London, June 196, Section 4, p 14 2 D F Kelsall, K J Reid and C J Restanck Continuous grinding to a small wet ball mill Part I A study of the influence of ball Continuous grinding in a small wet rod mill Part I2 天之前 Union Process SD Dry Grind Attritors are ruggedly built machines with specially designed, twospeed, high starting torque motors They are also equipped with jacketed, stainless steel tanks and tilting mechanisms for ease of cleaning and maintenanceDry Batch Or Continuous Production Mills Union Process1980年5月1日 Continuous grinding in a small wet ball mill, part III: a study of distribution of residence time Powder Technol (1969–1970) HE Rose et al A Treatise on the Internal Mechanics of Ball, Tube and Rod Mills; Anonymous, a (date unknown) Grinding Mills for the Rock Products, Cement and Chemical and Mining IndustriesScaleup procedure for continuous grinding mill design

Continuous grinding in a small wet ball mill Part V A study

DOI: 101016/00325910(73)800658 Corpus ID: ; Continuous grinding in a small wet ball mill Part V A study of the influence of media shape @article{Kelsall1973ContinuousGI, title={Continuous grinding in a small wet ball millA ball mill is a type of grinder containing various metal balls of different sizes that work on the principle of impact and attrition From: Bioresource Technology, 2022 the length of the cylinder is about equal to the diameter Most ball mills are continuous in operation, the feed entering at one end and discharging through the other end Ball Mill an overview ScienceDirect Topics2016年2月1日 A specific energybased size reduction model for batch grinding ball mills was reported in a previous paper (Shi and Xie, 2015) A discharge function modified from the Whiten classification efficiency equation has been incorporated in the size reduction model to extend its applications from batch grinding to continuous operationA specific energybased ball mill model: From batch grinding 2016年2月1日 A specific energybased size reduction model for batch grinding ball mills was reported in a previous paper (Shi and Xie, 2015) A discharge function modified from the Whiten classification efficiency equation has been incorporated in the size reduction model to extend its applications from batch grinding to continuous operationA specific energybased ball mill model: From batch grinding

.jpg)

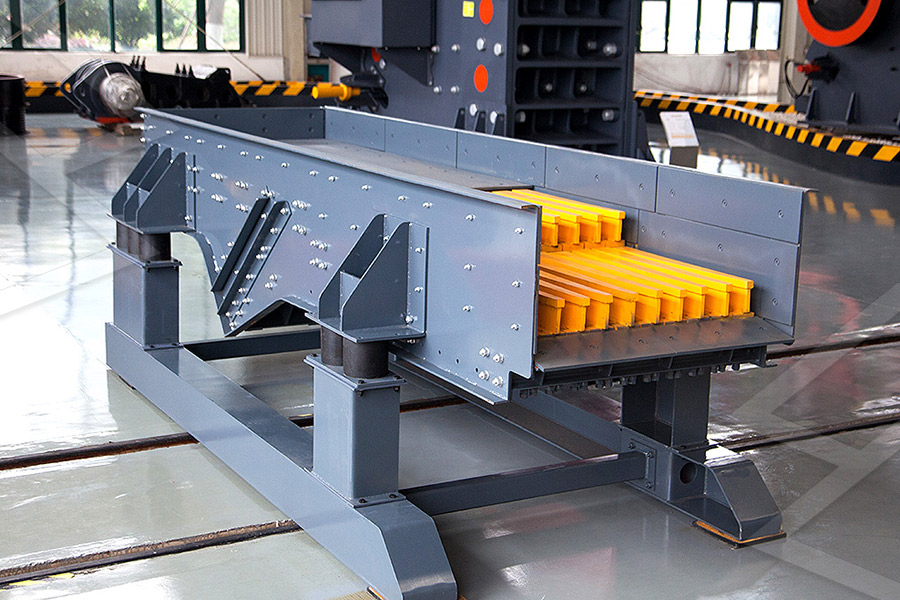

Selection Tips for Grinding Mills Union Process

4 天之前 Selecting the right grinding mills for your operation requires the serious consideration of a variety of factors, far beyond “what do I want to grind?” and “How fine do I want it?” A starter list of questions would include: Do you need lab grinding mills or production sized mills? Do you need to perform wet or dry milling?The slower the pumping rate, the longer the dwell time and the finer the grind The grinding media used in continuous grinding mills range in size from 2mm to 10mm in diameter Carbon steel, stainless steel, chrome steel and ceramic balls are commonly used media Continuous grinding mills can also be set up in seriesHow the Continuous Process Works Union ProcessContinuous ball mill has good grinding effect This operation mode enables the equipment to adjust production according to the state of the material, the grinding effect is better, and the adaptability is stronger Continuous ball mill has high production efficiency It can save the time of feeding and discharging, and improve the production Continuous Type Ball Mill for Industrial Use ball mills supplierThe grinding of quartz sand to produce high purity silica flour was studied using ceramic balls, ceramic cylinders or flint pebbles in a laboratory mill and three fullscale closed circuit mills Continuous grinding mill simulation using Austin's model

.jpg)

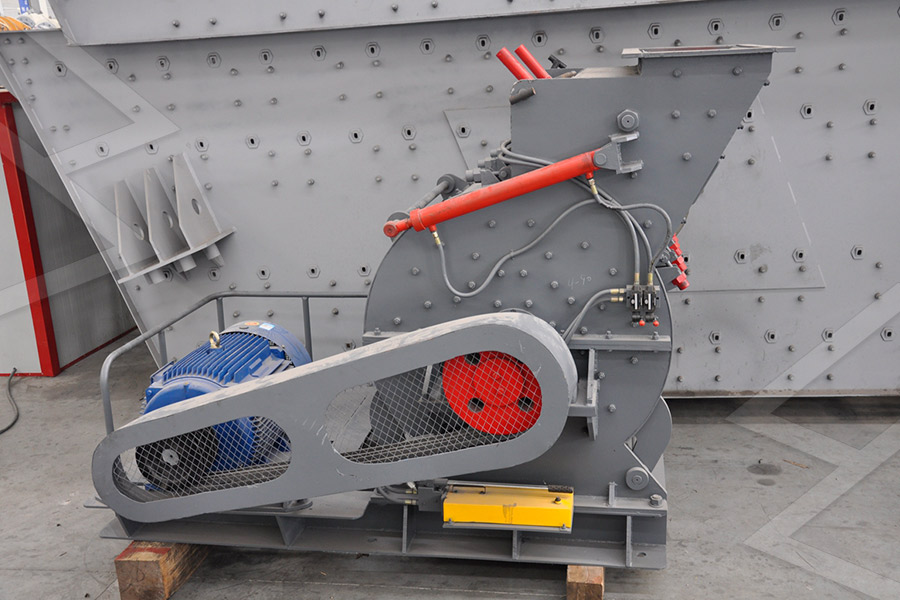

Exploring the components of ball mills NEWS SMMVIK

2024年10月13日 Exploring the components of ball mills Ball mills are versatile and widely used grinding machines in various industries, including mining, construction, and manufacturing They are designed to break down materials into smaller particles through friction and impact To perform effectively, ball mills rely on several key components working together1973年8月1日 The influence of change in grinding media shape on the grinding behaviour of trace quantities of quartz within an environment of calcite in a small continuous wet ball mill has been studied using steel spheres, cubes, long, short and equicylinders, and hexagonal “cylinders” Their dimensions were chosen so that a unit of each shape weighed the same as a Continuous grinding in a small wet ball mill Part V A study 4 天之前 Planetary ball mills share the same design as other basic ball mills – a grinding jar filled with media and rotated on its own axis But their unique design takes advantage of centrifugal force and the Coriolis effect to grind materials to a very fine or even micron size Attritors also can run in continuous mode, which is another Planetary Ball Mills 101 Union ProcessContinuous Ball Mill is useful for grinding coarse feed to get fine powder in single continuous operationIt used is for grinding Feldspar, Quartz, iron ore, manganese ore, Zircon, steatite, Ceramics, Cement, Pencil, Paint, Chemical, Ink, Marble, Coal, any types of minerals etcBall Mill Shalimar Engineering

.jpg)

Attrition Mills and Milling Union Process

1 天前 Wet Grinding Laboratory Mills Wet Batch Laboratory MillsWet Circulation Laboratory MillsChocolate Grinding Attrition MillsLimestone Slaker Ball Mill (CLS)Limestone Grinding Ball Mill (CL)Small Media Bead Mills (SDM) Wet Grinding Production Mills Wet Batch Production MillsWet Circulation Production MillsWet Continuous Production MillsChocolate Grinding Attrition 1973年5月1日 TXX influence of changes in grinding media load and density on the grinding behaviour of trace quantities of quartz within an environment of calcite in a small continuous wet ball mill have been studied using (a) ball loads ranging from 45% to 100% of the standard load of 1in balls, (b) a standard load of 1in pebbles and (c) standard loads of equicylinders with Continuous grinding in a small wet ball mill Part IV A study Continuous Grinding in a Small Wet Ball Mill Part III A Study of Distribution of Residence Time D F KELSALL, K1 REID alm C 1 RESTARICK CS LR O, Dircs:on of Chemical Engineering, Melbourne, Victoria (Australia) (Received August 6, 1969) SUMMARY The effect of changes in several grinding r,ariables on theflow characteristics of liquid and solids through a small Continuous grinding in a small wet ball mill Part III A study 2004年12月10日 Optimization of continuous ball mills used for finishgrinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time It can be summarised that for ball mills in Combigrinding plants the optimal L/D ratio is clearly below 30 For coarse feed material about 27 seems to be appropriate and about 23 for Optimization of continuous ball mills used for finishgrinding

.jpg)

Batch Ball Mill Grinding 911Metallurgist

2017年7月3日 In this way dry grinding was like wet grinding in the rod mill, as shown in tables 8 and 9 The peak of the power curve shown in table 14 at 150 pounds of ore is contrary to what would be predicted from the findings in wet grinding, Continuous grinding in a small wet ball mill, part III: a study of distribution of residence time Powder Technol, 3: 170178 Klimpel, RR and Austin, LG, 1970 Determination of selectionforbreakage functions in the batch grinding equations by nonlinear optimization Ind Eng(PDF) Scaleup procedure for continuous grinding mill design using Economy Ball Mill, a division of JSB Industrial Solutions, Inc manufactures Ball Mills that are diverse in applications and uses Since we are an OEM and our product line has been around for over 50 years, we can provide the experience and knowledge to enhance your process capabilities by applying our procedural based manufacturing methods to your process Ball Mills Economy Ball Mill/JSB Industrial Solutions IncThe effect of changes in the holdup weight of calcite environment in a small continuous wet ball mill on the grinding behaviour of quartz tracer solids has been studied The distribution of residence time and rate of breakage for the initial tracer size have been determined experimentally for holdup weights varying from 1350 to 7640 g and the Continuous grinding in a small wet ball mill Part II A study

Impact of ball size distribution, compartment configuration,

2022年11月1日 In this context, modeling of fullscale continuous ball mills could provide significant insights and help process design (King, 2001) Ball milling, where balls hit and grind particles in a rotating horizontal tube, is reported to be an inefficient unit operation (von Seebach et al, 1996, Fuerstenau and Abouzeid, 2002)The influence of changes in ball diameter on the grinding behaviour of trace quantities of quartz within an environment of calcite in a small continuous wet ball mill has been studied Rates of breakage for the initial tracer size and corresponding distribution of residence times have been determined experimentally, using balls with diameters Continuous grinding in a small wet ball mill Part I A study of 2022年11月1日 In this context, modeling of fullscale continuous ball mills could provide significant insights and help process design (King, 2001) Ball milling, where balls hit and grind particles in a rotating horizontal tube, is reported to be an inefficient unit operation (von Seebach et al, 1996, Fuerstenau and Abouzeid, 2002)Impact of ball size distribution, compartment configuration, 2012年6月1日 continuous steady state mills, the size reduction is treated as a continuous process Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate (PDF) Grinding in Ball Mills: Modeling and Process Control

.jpg)

Experimental characterization of chalcopyrite ball mill grinding

2021年11月1日 The energy consumptionbased characterization of different chalcopyrite grinding processes, performed in ball mills using both batch and continuous flow processing modes, is discussed in this section 41 Materials and 1973年6月1日 REFERENCES 1 D F Kelsall and K J Reid, The derivation of a mathematical model for brealage to a small continuous open circuit wet ball mill, Proc A 1 Ch E II Chem E Joint Meeting, London, June 196, Section 4, p 14 2 D F Kelsall, K J Reid and C J Restanck Continuous grinding to a small wet ball mill Part I A study of the influence of ball Continuous grinding in a small wet rod mill Part I2 天之前 Union Process SD Dry Grind Attritors are ruggedly built machines with specially designed, twospeed, high starting torque motors They are also equipped with jacketed, stainless steel tanks and tilting mechanisms for ease of cleaning and maintenanceDry Batch Or Continuous Production Mills Union Process1980年5月1日 Continuous grinding in a small wet ball mill, part III: a study of distribution of residence time Powder Technol (1969–1970) HE Rose et al A Treatise on the Internal Mechanics of Ball, Tube and Rod Mills; Anonymous, a (date unknown) Grinding Mills for the Rock Products, Cement and Chemical and Mining IndustriesScaleup procedure for continuous grinding mill design

Continuous grinding in a small wet ball mill Part V A study

DOI: 101016/00325910(73)800658 Corpus ID: ; Continuous grinding in a small wet ball mill Part V A study of the influence of media shape @article{Kelsall1973ContinuousGI, title={Continuous grinding in a small wet ball millA ball mill is a type of grinder containing various metal balls of different sizes that work on the principle of impact and attrition From: Bioresource Technology, 2022 the length of the cylinder is about equal to the diameter Most ball mills are continuous in operation, the feed entering at one end and discharging through the other end Ball Mill an overview ScienceDirect Topics