Cost Of Vertical Roller Mill Clinker Grinding

.jpg)

The Comprehensive Guide to Cement Plant Costs: An In

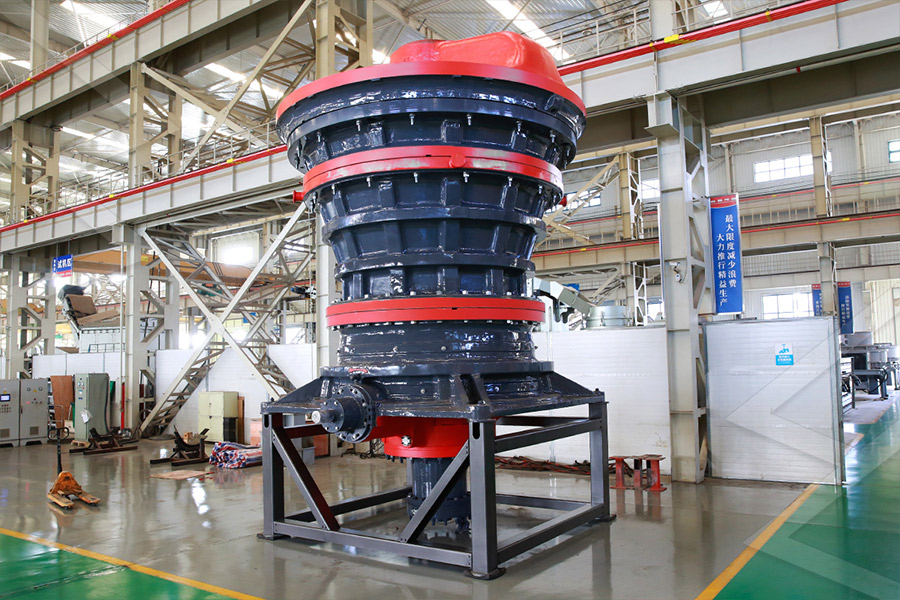

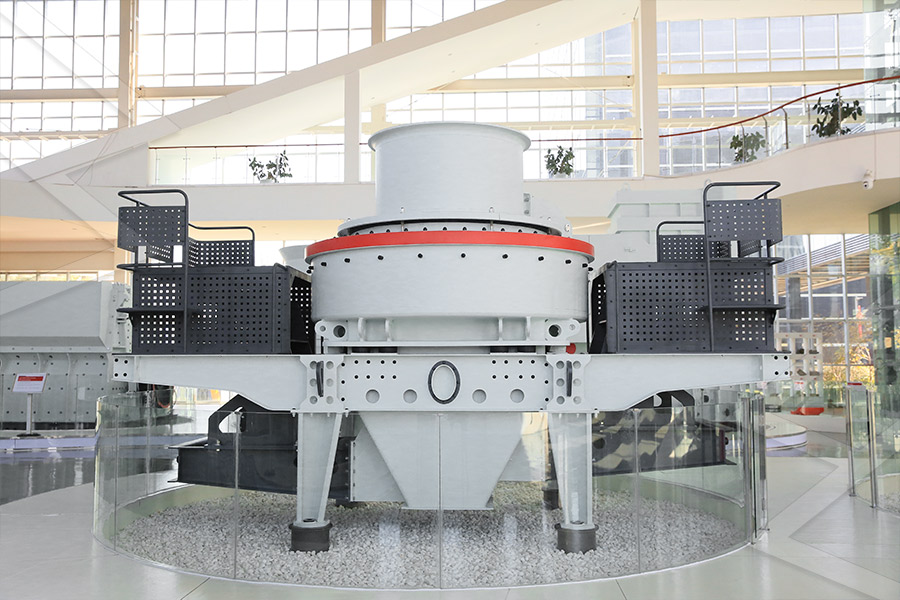

Vertical Roller Mills: 2050 tons/hour capacity, 10003000 kW motor power 3 Kiln System The kiln is the heart of the cement plant, where the raw mix is transformed into clinker through heating Equipment: Rotary kilns, preheaters, precalciners Rotary Kilns: 3562 meter diameter, 6090 Aside from the consumption of electrical energy, in which respect the vertical Cement grinding Vertical r2023年11月20日 The cost price of a vertical roller mill for cement can vary depending on several factors such as the size and capacity of the mill, the technology used, and the manufacturer vertical roller mill for cement cost price cmcrusher2023年3月4日 As an estimate, a small vertical roller mill for clinker grinding with a capacity of around 50100 tons per hour can cost anywhere from $155 million USD, while a larger mill cost of vertical roller mill clinker grinding CM Mining

.jpg)

Vertical roller mill for raw Application p rocess materials

2016年1月4日 Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It Vertical roller mills FLSmidth Cement2024年1月30日 The cost of vertical roller mill clinker grinding can vary depending on the size and scope of your project However, by using recycled or used materials whenever possible Cost of vertical roller mill clinker grinding NEWS SMMVIK 2021年1月1日 With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over the ball mill system Review on vertical roller mill in cement industry its

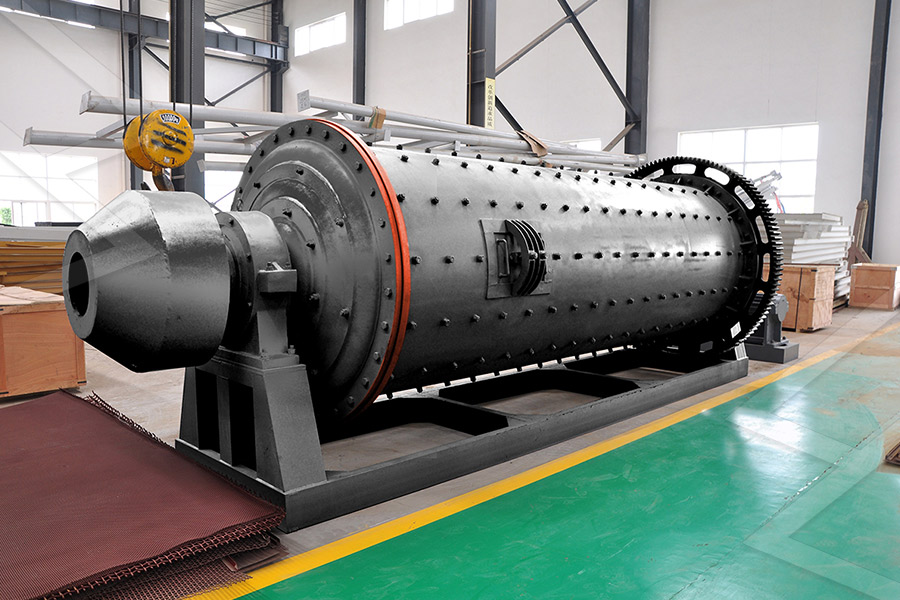

Cement grinding Vertical roller mills VS ball mills

Aside from the consumption of electrical energy, in which respect the vertical roller mill is superior compared to a ball mill, other factors – although to a lower extent – affect the cost of operation, such as cost of grinding aid, cost of fuel We can design and manufacture vertical roller mills of diversified specifications and models for raw meal, cement, and slag comminuation systems in cement clinker production lines with capacity up to 10,000t/d To continuously meet Vertical Roller Mill (VRM)SinomaLiyang Heavy 23 小时之前 Cement qualities for nonstructural applications with low specific surface (low Blaine) are no technical challenge for VRMs, unpretentious Grinding Aids will show a perfect SikaGrind® for vertical roller mills2024年12月13日 A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in Energysaving and Efficient Vertical Roller Mill

.jpg)

Cement grinding Vertical roller mills versus ball mills

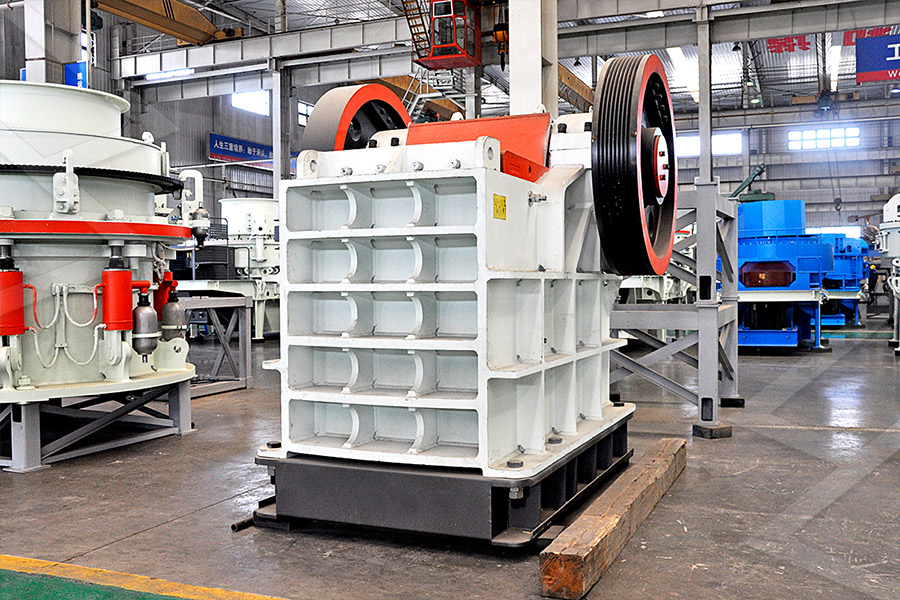

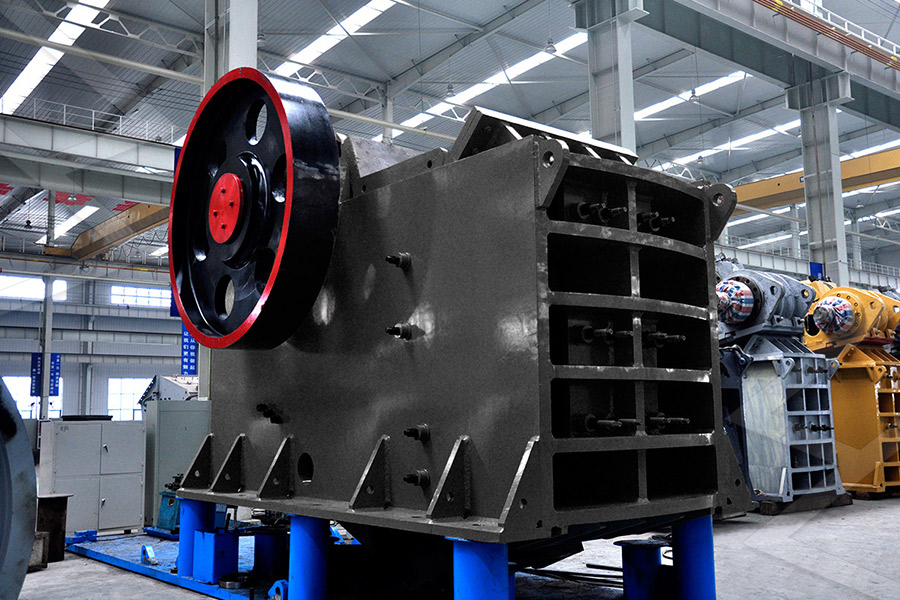

2016年1月23日 Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system However, despite these benefits 23 小时之前 The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a SikaGrind® for vertical roller mills2024年1月3日 Vertical roller mills are widely used for especially grinding of coal, cement raw materials, clinker and minerals like bauxite, phosphate, magnesite, etcPerformance Evaluation of Vertical Roller Mill in Cement 2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study per‐ formed on a EnergyEfficient Technologies in Cement Grinding

.jpg)

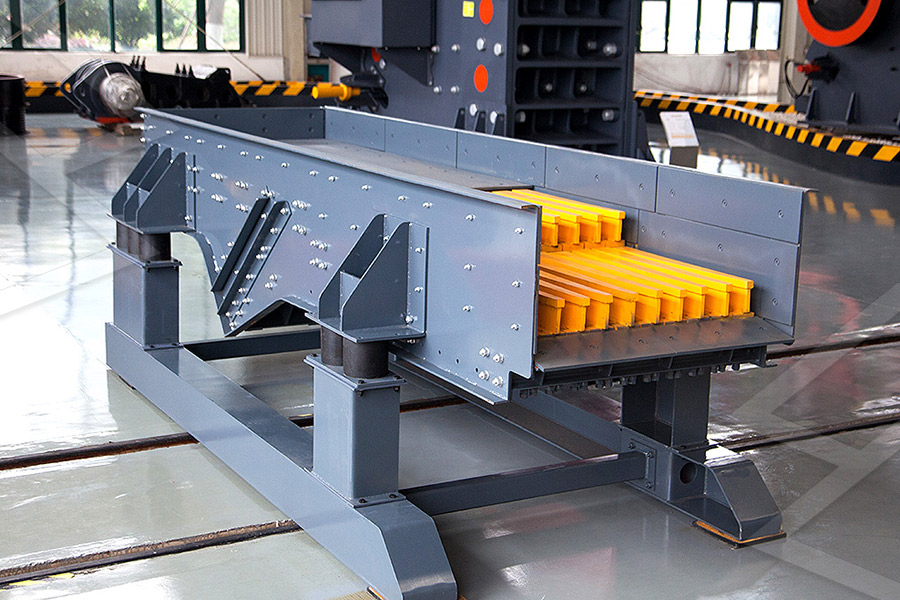

Grinding Process Optimization Featuring Case Studies

2023年12月6日 raw material grinding, a modular vertical roller mill with 5 m table diameter and 4 rollers was added The existing kiln systems were partly modernized, one kiln system was replaced by new system 4 小时之前 The cost of vertical roller mill clinker grinding is a key factor to consider when choosing a grinding method Vertical roller mills have many advantages over traditional ball mills, such as higher grinding efficiency, lower power consumption, and smaller physical footprint However, the initial cost of vertical roller mill clinker grindingmd2022年10月20日 mills This compares with the compression mechanism, as well as attrition, utilised in both highpressure grinding rolls (HPGRs) and vertical roller mills (VRMs) The Bond Ball Mill Work Index (BBMWi) is widely used to measure the grindability of a mineral in kWh/t2 In reference to clinker grinding, the following are typicalGRINDING Grinding options for slag and pozzolan PEC 2019年1月3日 Clinker grinding technology is the most energyintensive process in cement manufacturing Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 per cent of total energy consumed and account for most of the manufacturing cost Since the increasing energy cost started burning the benefits significantly, Clinker grinding technology in cement manufacturing

.jpg)

Picture: Loesche GmbH, Germany CEMENT SikaGrind®

2024年7月1日 Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press High increase in early strength SikaGrind®120 Moderate treatment cost Typical dosage: 015% Contains Chlorides Limestone is much easier to grind than clinker The common intergrinding of limestone A Vertical Roller Mill (VRM) is an advanced and efficient grinding machine commonly used in the cement industry for grinding raw materials and clinker VRMs have become increasingly popular due to their ability to produce finer products with lower energy consumption compared to traditional ball mills Advantages of Vertical Roller Mills:Vertical roller mill vs ball mill for cement grinding: HLM vertical grinding mill and vertical roller mill is a highefficiency energysaving advanced pulverizing equipment integrating drying, pulverizing, grading and conveying, which has been researched and developed by Guilin Hongcheng Company for more than 20 years Hongcheng HLM vertical grinding mill has the advantages of high grinding efficiency, low power HLM Vertical Grinding Mill Vertical Roller Mill hcmills4 Mar 2023; A vertical roller mill is a type of industrial equipment used to grind materials into fine powders, such as cement clinker vertical roller mill have the advantage of being more energyefficient than traditional ball mills and can typically grind materials to a finer particle size vertical roller mill clinker grinding The cost of a vertical roller mill for clinker grinding can cost of vertical roller mill clinker grinding CM Mining

Cost of vertical roller mill clinker grinding NEWS SMMVIK

2024年1月30日 The cost of vertical roller mill clinker grinding may seem high at first glance, but it is actually very efficient This process can save you money in the long run by reducing wear and tear on your equipment This type of grinding uses a series of rollers to crush the material instead of relying on a single rotating wheel This helps to reduce Relative investment costs that a high material surface unbalance prevails in the mill when grinding all types of clinker, thus requiring a grinding aid at all times The higher the fineness, the more grinding aid that must be used to restore the feed particles to a balanced state Also work in Vertical Roller Mills Good ventilation Everything you need to know about clinker/cement Grinding2001年10月1日 LOESCHE mills for grinding of clinker and slag and for the production of cements with interground additives but at the cost of marginally lower recoveries as predicted from pilot studies This paper reports on the systematic geometallurgical approach to improve mineral resource utilisation by successfully processing lithified ore Loesche vertical roller mills for the comminution of ores and minerals Vertical roller mills (VRM) have become increasingly popular in recent years, as more cement producers look to increase their use of clinker substitute materials instead of importing clinker to meet localized rises in cement demand The demand for cement has grown rapidly in recent years, creating a need for a more efficient way to grind clinker and other raw materials used in How does vertical roller mill work? ball mills supplier

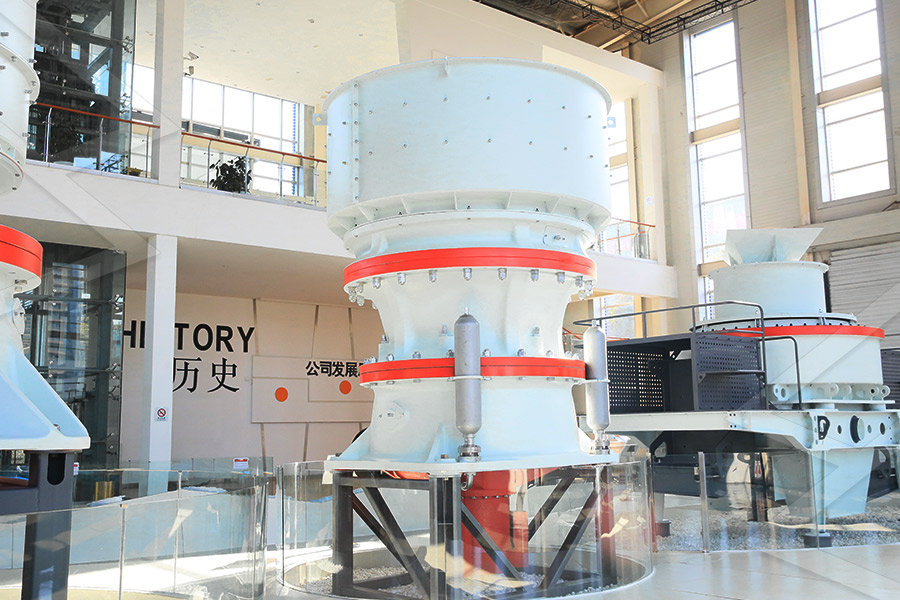

Vertical Roller Mill in Cement Manufacturing Plant

2023年7月4日 A cement vertical roller mill (VRM) is a type of grinding equipment commonly used in cement plants for raw material grinding and cement grinding It is an energyefficient alternative to traditional ball mills, as it utilizes rollers to grind and crush the materials between a rotating grinding table and a set of rollers mounted on a vertical axis2023年11月16日 HRM vertical mill series vertical mills are widely used in different industries such as cement, electricity, metallurgy, chemical and nonmetal mineral for the grinding of cement raw meal, clinker, mining slag, steel slag, coal, gypsum, calcite, pyrophyllite, quartz and limestone powder for sulfur treatment in power plant, etcVertical Roller Mill Vertical Roller Mill and Vertical Grinding MillSlag Vertical Roller Mill, Cement Grinding Mills Price, Clinker Vertical Roller Mill For Sale, US $ 23200 23200 / Set, Manufacturing Plant, Construction works , Energy Mining, None, ProvidedSource from Henan Baichy Machinery Equipment Co, Ltd on AlibabaSlag Vertical Roller Mill, Cement Grinding Mills Price, Clinker Disadvantage of limestone powder ultrafine vertical roller mill: 1 Limestone powder ultrafine vertical roller mill is not suitable for grinding hard and abrasive materials, with short service life and frequent maintenance Moreover, its wear Limestone Powder Ultrafine Vertical Roller Mill

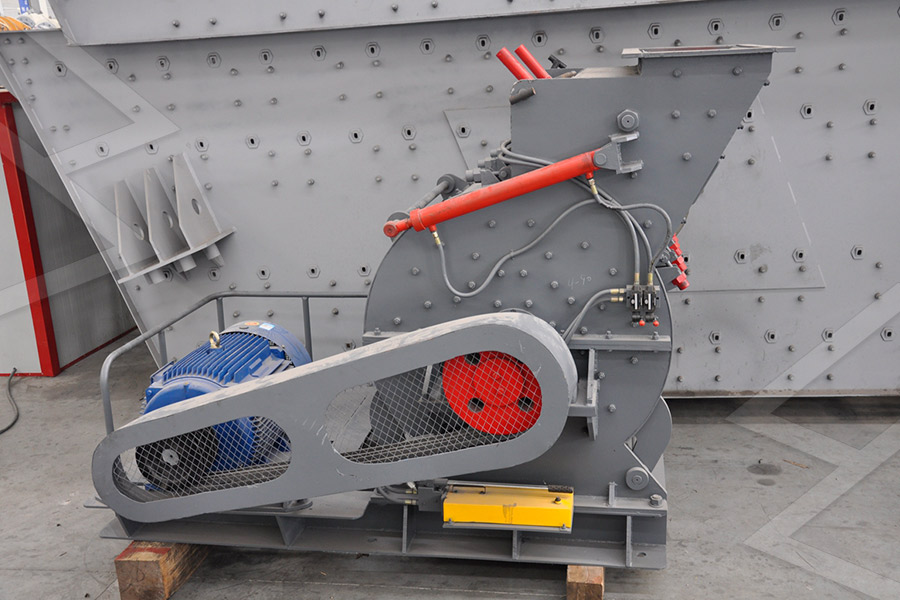

EnergyEfficient Technologies in Cement

2016年10月5日 Performance of grinding circuits has been improved in recent years by the development of machinery such as highpressure grinding rolls (HPGR) (roller presses), Horomills, highefficiency classifiers and vertical 2017年8月12日 vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and mostPROCESS OPTIMISATION FOR LOESCHE GRINDING What is Slag Vertical Roller Mill, Cement Grinding Mills Price, Clinker Vertical Roller Mill for Sale, Raymond mill manufacturers suppliers on Video Channel of MadeinChina Cement Grinding Mills Price, Clinker Vertical Roller Mill for Sale Roller Mill US$12,00000 / set View Recommend for you; What is BestSelling Coal Dust What is Slag Vertical Roller Mill, Cement Grinding Mills Price, Clinker 4 天之前 There are six grinding systems available for the grinding of clinker Conventional closed circuit system consisting of ball mill, bucket elevator and high efficiency separator Pre grinding with a roller press and subsequent finish grinding CLINKER GRINDING UNIT PROCESS ENGINEERING

Coal Stone Slag Cement Grinding Clinker Vertical Roller Mill Price

Coal Stone Slag Cement Grinding Clinker Vertical Roller Mill Price No reviews yet Henan Hongji Mine Machinery Co, Ltd Custom manufacturer 17 yrs CN Raw Meal Mill Cement Clinker Grinding Vertical Roller Raw Mill $3,00000 Min order: 1 set Easy Return 1500TPD Rotary Kiln Cement Production Line Cement Making Machinery PlantThis article will explore the application of vertical roller mills in the cement industry, including their benefits, efficiency, and ecofriendly features Understanding Vertical Roller Mill Technology Vertical roller mill (VRM) is a type of grinding machine used to grind materials into extremely fine powder, commonly used in the cement industryApplication of Vertical Roller Mill in Cement Production2024年10月13日 The Vertical Roller Mill in Cement Production: The vertical roller mill is a stateoftheart drying and grinding facility that is widely used in the cement industry It is primarily used for the grinding of cement raw materials, clinker, slag, and other materialsThe role of vertical roller mills in the cement industry NEWS LM Vertical Roller Mill LM Vertical Grinding Mill integrates five functions of crushing, grinding, powder selection, drying and material conveying the investment cost of the mill is low Low operation costs The rollers are equipped with roller sleeve, which can be replaced easily, the rollers are not easy to be worn out and so the cost LM Vertical Roller Mill, Vertical Mill Manufacturer

.jpg)

Energysaving and Efficient Vertical Roller Mill

2024年12月13日 A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in 2016年1月23日 Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system However, despite these benefits Cement grinding Vertical roller mills versus ball mills23 小时之前 The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a SikaGrind® for vertical roller mills2024年1月3日 Vertical roller mills are widely used for especially grinding of coal, cement raw materials, clinker and minerals like bauxite, phosphate, magnesite, etcPerformance Evaluation of Vertical Roller Mill in Cement

.jpg)

EnergyEfficient Technologies in Cement Grinding

2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study per‐ formed on a 2023年12月6日 raw material grinding, a modular vertical roller mill with 5 m table diameter and 4 rollers was added The existing kiln systems were partly modernized, one kiln system was replaced by new system Grinding Process Optimization Featuring Case Studies 4 小时之前 The cost of vertical roller mill clinker grinding is a key factor to consider when choosing a grinding method Vertical roller mills have many advantages over traditional ball mills, such as higher grinding efficiency, lower power consumption, and smaller physical footprint However, the initial cost of vertical roller mill clinker grindingmd2022年10月20日 mills This compares with the compression mechanism, as well as attrition, utilised in both highpressure grinding rolls (HPGRs) and vertical roller mills (VRMs) The Bond Ball Mill Work Index (BBMWi) is widely used to measure the grindability of a mineral in kWh/t2 In reference to clinker grinding, the following are typicalGRINDING Grinding options for slag and pozzolan PEC

Clinker grinding technology in cement manufacturing

2019年1月3日 Clinker grinding technology is the most energyintensive process in cement manufacturing Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 per cent of total energy consumed and account for most of the manufacturing cost Since the increasing energy cost started burning the benefits significantly, 2024年7月1日 Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press High increase in early strength SikaGrind®120 Moderate treatment cost Typical dosage: 015% Contains Chlorides Limestone is much easier to grind than clinker The common intergrinding of limestone Picture: Loesche GmbH, Germany CEMENT SikaGrind®